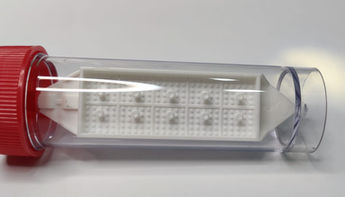

פיתוח תבניות להזרקת פלסטיק

פיתוח וייצור תבניות

פיתוח תבניות הוא שלב קריטי בייצור הזרקת פלסטיק, הדורש מומחיות ודיוק.

אנו בפלסטומולד מתמחים במתן שירותי פיתוח וייצור תבניות מקיפים,

תוך מינוף הידע העמוק שלנו בתעשייה כדי לייעל את התהליך.

אנו לוקחים בחשבון גורמים שונים,

כגון חומר גלם, אופן חליצת המוצר, סוג כניסת חומר, טיב שטח, מנגנוני קירור,

עגלות צד, סוגי פלדה, כמות מובלעות, יכולות הזרקה כפולה ועוד,

כדי להבטיח את האיכות והיעילות הגבוהות ביותר.

גישתנו:

1. תכנון תבניות תוך שיתוף פעולה עם הלקוח:

בפלסטומולד אנו עובדים בשיתוף פעולה הדוק עם לקוחותינו כדי לפתח ולתכנן תבניות המתאימות למפרט המוצר. בתהליך התכנון אנו מנתחים היטב את המוצר ודרישותיו, תוך התאמתם לעיצוב התבנית המתאים ביותר, שמבטיח את התוצאה הרצויה מבחינת איכות, עלות ותועלת.

2. ייצור תבניות מתקדם:

ברשותנו מפעל תבניות משוכלל הממוקם במעבדתנו בחולון, וכן שותפויות עם מפעלים בעלי מוניטין בסין.

בהתאם לצרכי הלקוח ולשיקולים של איכות, מחיר וזמן אספקה, אנו בוחרים את מקום הייצור המתאים ביותר לייצור התבניות.

בכל אחד מאתרי הייצור, אנו מבטיחים שכל התבניות מיוצרות בסטנדרטים הגבוהים ביותר של דיוק ועמידות.

למה לבחור בפלסטומולד:

1. מומחיות וניסיון:

עם הניסיון הרב שלנו בפיתוח וייצור תבניות, אנו מביאים שפע של מומחיות לכל פרויקט. צוות המקצוענים שלנו בקיא היטב במורכבות של הזרקת פלסטיק, ויכול לספק תובנות והמלצות חשובות כדי לייעל את תכנון התבנית שלך.

2. ציוד חדיש ומשוכלל:

מפעל התבניות שלנו מצויד במכונות מתקדמות ובטכנולוגיה חדישה על מנת להבטיח ייצור תבניות איכותיות. אנו משקיעים בכלים ובטכניקות העדכניות ביותר כדי לספק דיוק ויעילות, וכתוצאה מכך התבניות עונות על המפרט המדויק שלך.

3. בקרת איכות:

אנו מנהלים תהליך בקרת איכות קפדני כדי להבטיח את איכות התבניות שלנו. כל תבנית עוברת בדיקות יסודיות על מנת להבטיח את הפונקציונליות, העמידות והתאימות שלה לתהליך ההזרקה.

4. פתרונות לשיפור עלות-תועלת:

בפלסטומולד אנו מבינים את החשיבות של עלות-תועלת. אנו שואפים לספק תמחור תחרותי מבלי להתפשר על איכות, ולעזור לך להשיג את ההחזר הטוב ביותר על ההשקעה שלך.

בחרו בפלסטומולד כשותף המהימן שלכם לפיתוח וייצור תבניות.

צרו איתנו קשר עוד היום כדי לדון בדרישות הפרויקט שלכם, ונהפוך את הרעיונות שלכם למציאות.